Highly hardened beads that are highly abrasion resistant and resistant to cracking and chipping!

Features

- Excellent wear resistance

In the case of hardened materials, the wear resistance is superior to that of zirconia beads. - High Purity

These are high-purity alumina beads with a purity of 99.99% or higher.

Contamination of components other than alumina is practically zero, making them suitable for grinding and dispersing electronic material materials that are sensitive to radioisotope contamination. - Excellent corrosion resistance

It has excellent corrosion resistance to acids and alkalis. It also does not deteriorate in hot water, as is the case with zirconia. - Energy-saving dispersion and pulverization

Since the density is almost 2/3 that of zirconia, it can be crushed with 2/3 filling weight. In addition, energy consumption (power consumption) may be saved.

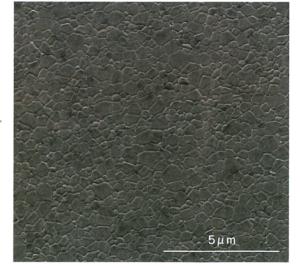

SEM photograph of the crystal structure of the beads

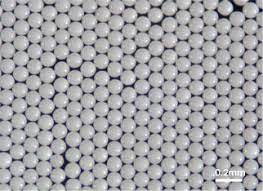

Size

Φ0.1mm;Φ0.2mm;Φ0.3mm;Φ0.4mm;Φ0.5mm

density

| Density | 3.9g/cm3 |

| Filling density | 2.4g/cm3 |

Impurity Analysis Example

| chemical element | Na | K | Si | Fe | Mg | Ca | Cr |

| content | 8 | 4 | 10 | 8 | 3 | 3 | 2 |

(ppm)