High-purity, ultra-fine ceramics powder produced from aluminum chemical synthesis method.

Developed based on the synthesis of ammonium dawsonite (NH4AlCO3(OH)2).

Application

- High-strength, wear-resistant material: artificial bones/dental materials, bearings, etc.

- Electronic materials: IC boards/semiconductor manufacturing jigs, sensors, etc.

- Optical material: translucent ceramics, ruby, YAG, etc.

- Others: Various fillers, synthetic spinel, catalyst carriers, etc.

Low temperature sinterable alumina

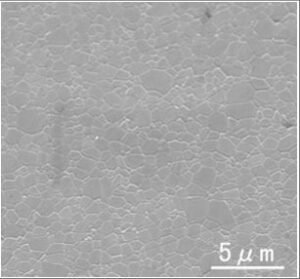

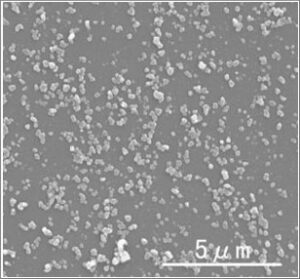

Taimicron for sintering is a high-purity α-alumina powder that can be sintered and densified at extremely low temperatures because the primary particles are fine and single particles.

Features

- Ultra-fine ceramics powder with high-purity of more than 99.99%.

- Low temperature sintered and densified alumina.

It densifies to 98% or more of the theoretical density by firing at 1250°C to 1300°C.

- Excellent sintered powder that obtain the original characteristics of alumina.

High-strength, high-hardness, high wear-resistance and corrosion resistance ceramics.

- Easy to obtain translucent ceramics.

By HIP sintering, etc., it becomes translucent ceramics.

Technical data

Purity analysis

| AL2O3 (%) |

Impurities (ppm) | ||||||||||

| Si | Fe | Na | K | Ca | Mg | Cu | Cr | Mn | U | Th | |

| >99.99 | 10 | 8 | 8 | 3 | 3 | 2 | 1 | <1 | <1 | <0.004 | <0.005 |

Characteristics

| Grade | Low temperature sinterable alumina | ||||||

| TM-UF | TM-DA | TM-DAR | TM-5D | ||||

| Crystalline form | α | α | α | α | |||

| BET Specific surface area(m2/g) | 17 | 12.5 | 13.5 | 9 | |||

| Primary particle size(㎛) | 0.09 | 0.12 | 0.12 | 0.2 | |||

| Bulk density(g/cm3) | 0.8 | 0.8 | 0.9 | 0.8 | |||

| Tapped density (g/cm3) | 1 | 0.9 | 1 | 1.1 | |||

| Pressed density(g/cm3) | 2.3 | 2.2 | 2.3 | 2.3 | |||

| Sintered density(g/cm3) | 3.93 | 3.95 | 3.96 | 3.93 | |||