✔ Inspection of striae (uneven areas) in optics device

✔ Inspection for foreign matter, air bubbles and surface scratches and polishing marks

✔ Optimal equipment for inspecting uneven polishing, such as uneven polishing of orange peel

■Vertical type

|

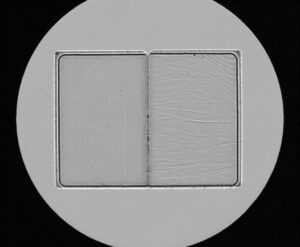

■Inspect sample ~ IR cut color glass filter  |

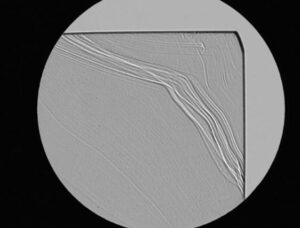

What is striae

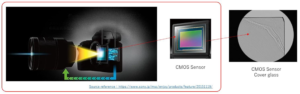

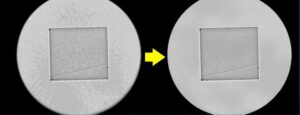

Striae is one of defect in glass products and a phenomenon of refractive index ununiformity with mixing different composition. We show you an striae evaluation example of a cover glass for CMOS camera module below.

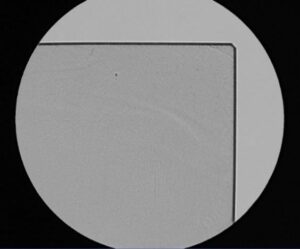

If the cover glass has a vein "Distortion" appears in the captured image

* If there is striae in the coated or bonded state of the optical components, the image captured in the same way will be "distorted", which will affect the image quality.

* There is no problem with optical design software, but if the actual image is distorted, it may be caused by the "striae" of the optical parts.

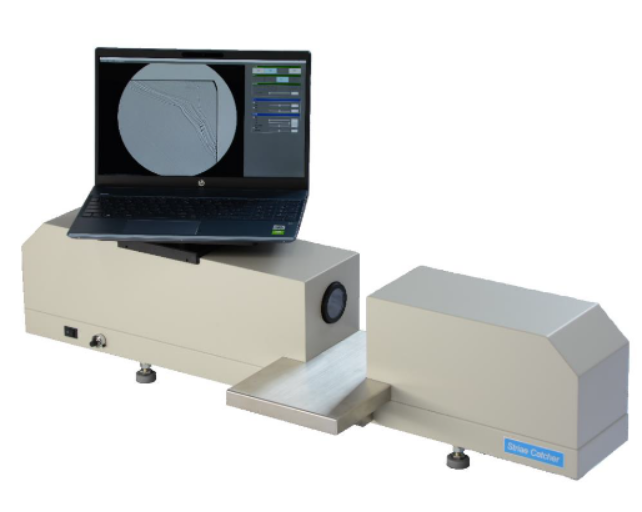

About LSC-5100

It is a striae inspection device that uses the shadow graph method as the inspection method. Insert optical components into the depression of the device to transmit light, and you can observe the striae in real time.

In addition, even though it is a striae inspection device, it can detect foreign substances, air bubbles, surface scratches, and other defects such as uneven polishing such as orange peel . Therefore, it is playing an active role as a "device that pleases customers" in the quality control department at the production site.

Feature

- Dedicated software Clear Back eliminates mottled patterns caused by optical elements in the equipment.

If the cover glass has a vein "Distortion" appears in the captured image

- Judgment on defective products that are very close to good products becomes easy. So it helps to shorten material inspection time.

Applicable material

- Quartz wave plate

- Optical filter

- Optical lens (Except parallel substrates, others are observed by soaking them in refracting liquid.)

Specification

| Model | STRIAE INSPECTION DEVICE LSC-5100 | ||||||||

| Method | Shadow graph method | ||||||||

| Evaluation Range | Approx. Φ45mm | ||||||||

| Sample Installation Space (Height) | Approx. 100mm | ||||||||

| Light source | High brightness blue LED | ||||||||

| Wavelength | 450~465nm | ||||||||

| Effective pixels | 1080(H)×824(V) | ||||||||

| Arrange light fuction | Volume dimming | ||||||||

| Size | Horizontal type (standard) W1030×D160×H205mm Vertical type (option) W380×D455×H1245mm |

||||||||

| Weight | 29kg | ||||||||

| Including | Sample stand / body cover | ||||||||

| Option | Vertical stand (weight: 10kg) | ||||||||

| Measurement environment | 10~35℃、Humidity 20~80% (No condensation) | ||||||||

| Power supply | AC100-240V , 50/60Hz , Power consumption 7W | ||||||||

| Monitor max resolution | 1920×1200 (24 inch wide) | ||||||||

| Compatible OS | Windows10(64bit) Japanese / English | ||||||||